Woodura

Strong and durable with Woodura®

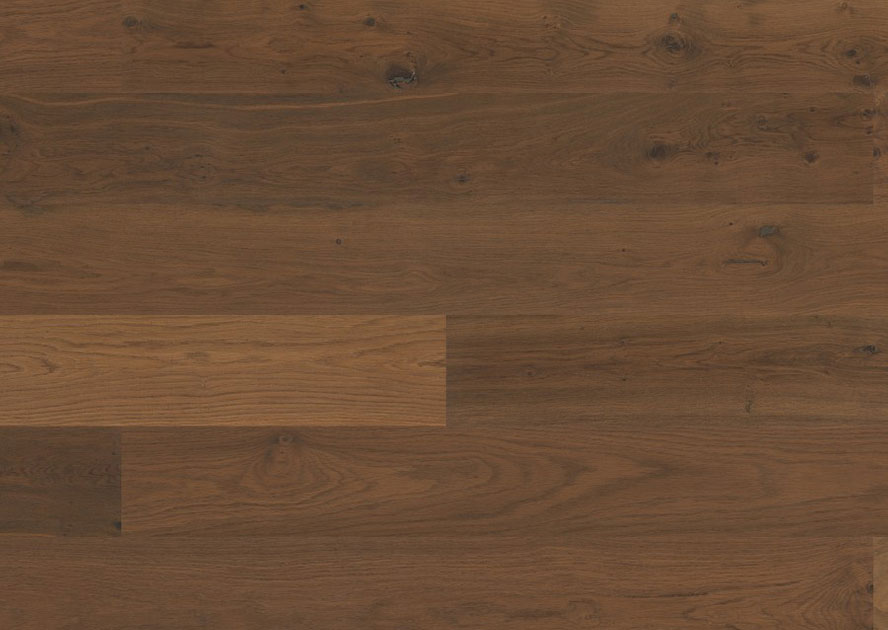

These hardened wood floors feature the unique Woodura technology, which allows the compression and hardening of wood, resulting in three times stronger floors than conventional wood floorboards. The Woodura solution is a technological advancement in the actual wood floor production process and it is as innovative as the 3-layer parquet was in 1944.

A significantly stronger, dent- and water-resistant surface that never needs to be sanded is produced via hardening process. Ten times more flooring from the same amount of timber can be generated, by using thinner surface layers during production. Thus, the floor is more cost-effective and its environmental impact is minimised.

Only FSC-certified wood sourced from the lush forests of Croatia are used to create these hardened wood floors.

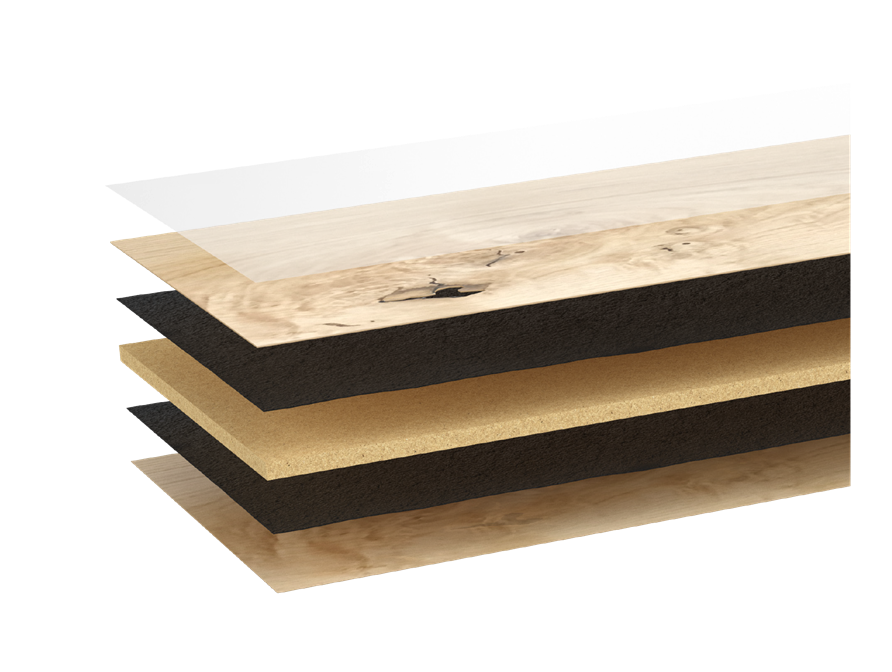

Product composition

- Surface treatment consisting of hardwax oil or matt lacquer

- Compressed and hardened surface layer of wood

- Compressed and hardened wood-based powder layer

- Wooden core of high quality moisture resistant HDF-board with hardened surfaces at the top and bottom

- Compressed and hardened wood-based powder layer

- A condensed and hardened wood balancing layer

The tough pro matt lacquer

These floors are incredibly durable due to the new pro matt lacquer surface treatment, which is so far the best kind. They are ideal for crowded areas in hotels, shops, workplaces, and cafés, as well as a high-traffic room in your house. The floor is easy to clean and stain-resistant thanks to this pro matt lacquer finish.

Hardened wood floors with a brushed surface

Wide planks of the hardened wood range 3.0 are available with a long-awaited brushed surface that elegantly draws attention to the oak’s structure. With the benefits of lacquer, which makes the floors simpler to clean and maintain, the brushed surface offers the floors a beautiful appearance and is reminiscent of the structure of a natural, oiled wooden floor.

• Care instructions (PDF)

• Installation instructions (PDF)

• Technical sheets will be provided upon request